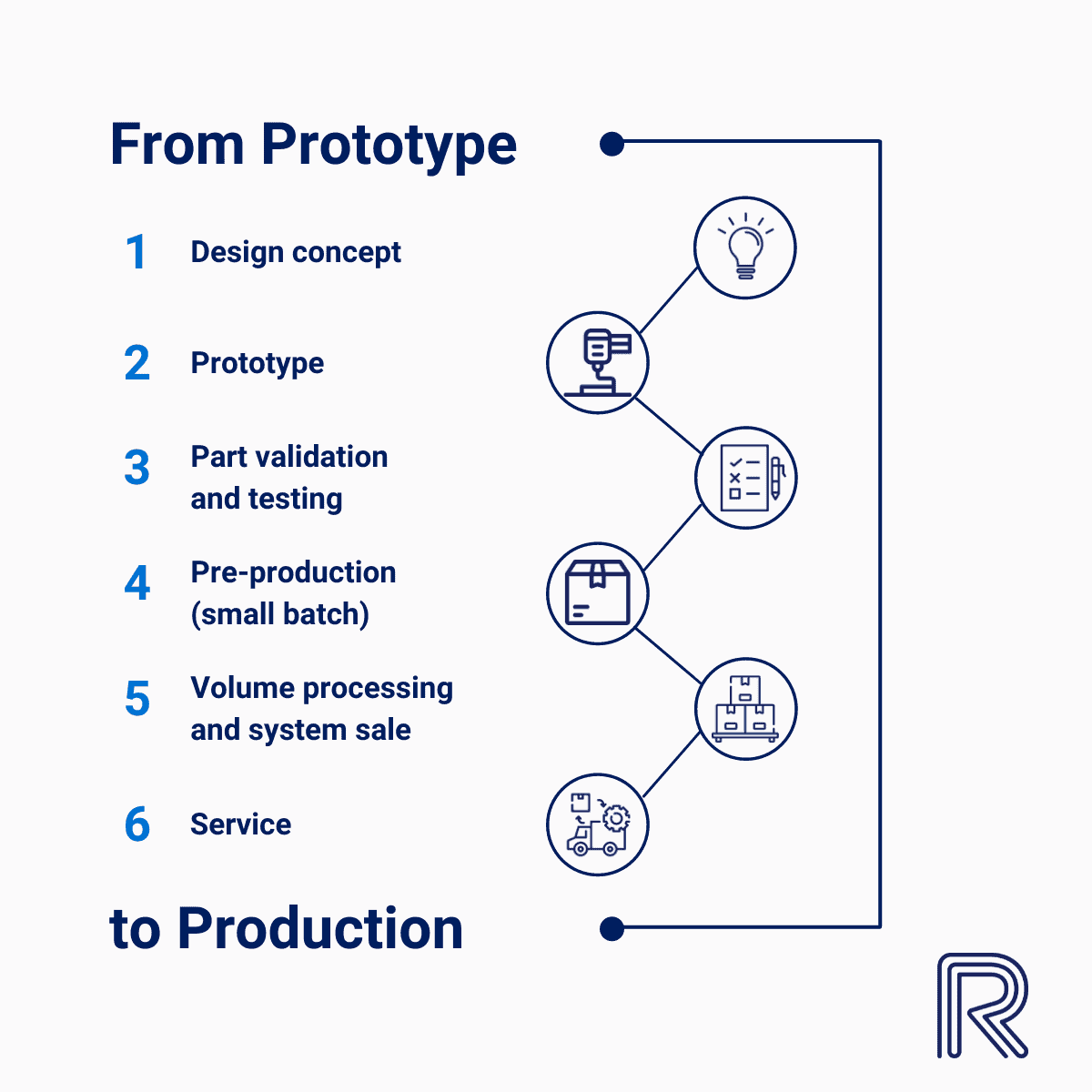

Robafoam is able to help a customer’s sealing requirements at any stage of its production. Whether you are in the initial design stage and still adapting CAD designs, or you have a finished product in production, we can offer sealing advice and support. In this blog article, we look at the different stages that our customers approach us at and give some more information on how we can help.

Design concept

The easiest point for us to offer advice on when looking at a customer’s part is as early in the design process as possible. By looking at the functional aspects of a seal within a part right at the beginning of the CAD stage, it means that the design can be adapted, if necessary, without the costs and stress which may occur if the part has been moved onto the prototype or production phase.

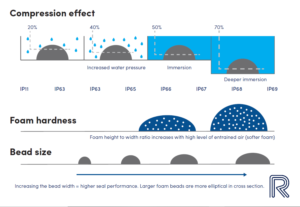

If you are currently at design concept stage, Robafoam has 30 years of experience to advise how best to incorporate a high performance robotically applied seal. We will evaluate a CAD design and offer free design advice, taking into consideration joint design, fixing points, bolt locations, compression control and the part material to work out the best type of seal for the part. We can adapt the bead size, shore hardness and take into consideration the impact of compression to ensure the part performs as expected. This is particularly important when looking to achieve an Ingress Protection (IP) rating for the part.

We are also happy to sign an NDA to ensure protection of your product if necessary.

Prototype

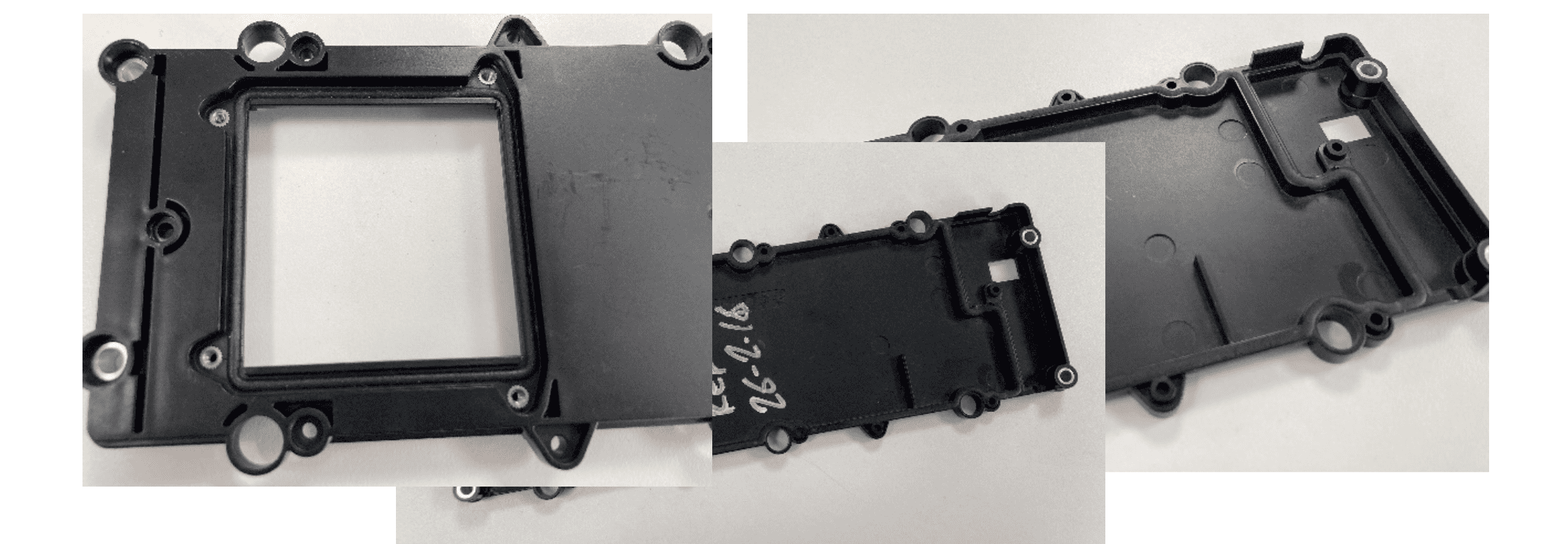

Most of the time our customers approach us for sealing support when they are in the prototype stage. Often the part will have been approved in the CAD stage but, once testing begins on the prototype, leaking or other issues will become apparent, and designers are asked to look for new sealing options to overcome these issues.

If you have moved onto the prototype stage of your part, we’re able to apply seals to one off 3D printed models for testing and can help with advice to develop the seals if required. We also offer ongoing project support throughout the development phases of part evolution. The only requirement we have is that the printed rapid prototypes are made from a thermally stable material (in an thermal oven at 80° for 10 minutes).

Our dedicated lab facility means that designers can come in for on site support and advice with our team and see how the seal could be adapted to overcome any failures in testing that may have been encountered.

We also offer our own on site testing, including composite/adhesion testing, IP rating evaluation through the use of water immersion and a high pressure water spray. A key benefit to our lab facility is the size of the production cell, which is able to work with parts up to 2 metres x 3 metres in size.

Preproduction (small batch)

Once through the prototype phase, the part may then need to be processed in small batches for further testing or development, while hard tooling is produced or the company waits for production equipment to be delivered and installed for larger volume production. Robafoam can support parts made with soft tooling and during this preproduction phase as we have no minimum order quantity requirements. This is perfect to help refine the process before it moves onto larger scale production, allowing the part to be tested and checked within the final product. It’s also an invaluable phase for customers process engineers can appreciate refine methods in advance of bringing a sealing system ‘in house’, as discussed below in system purchasing.

Volume processing – contract gasketing

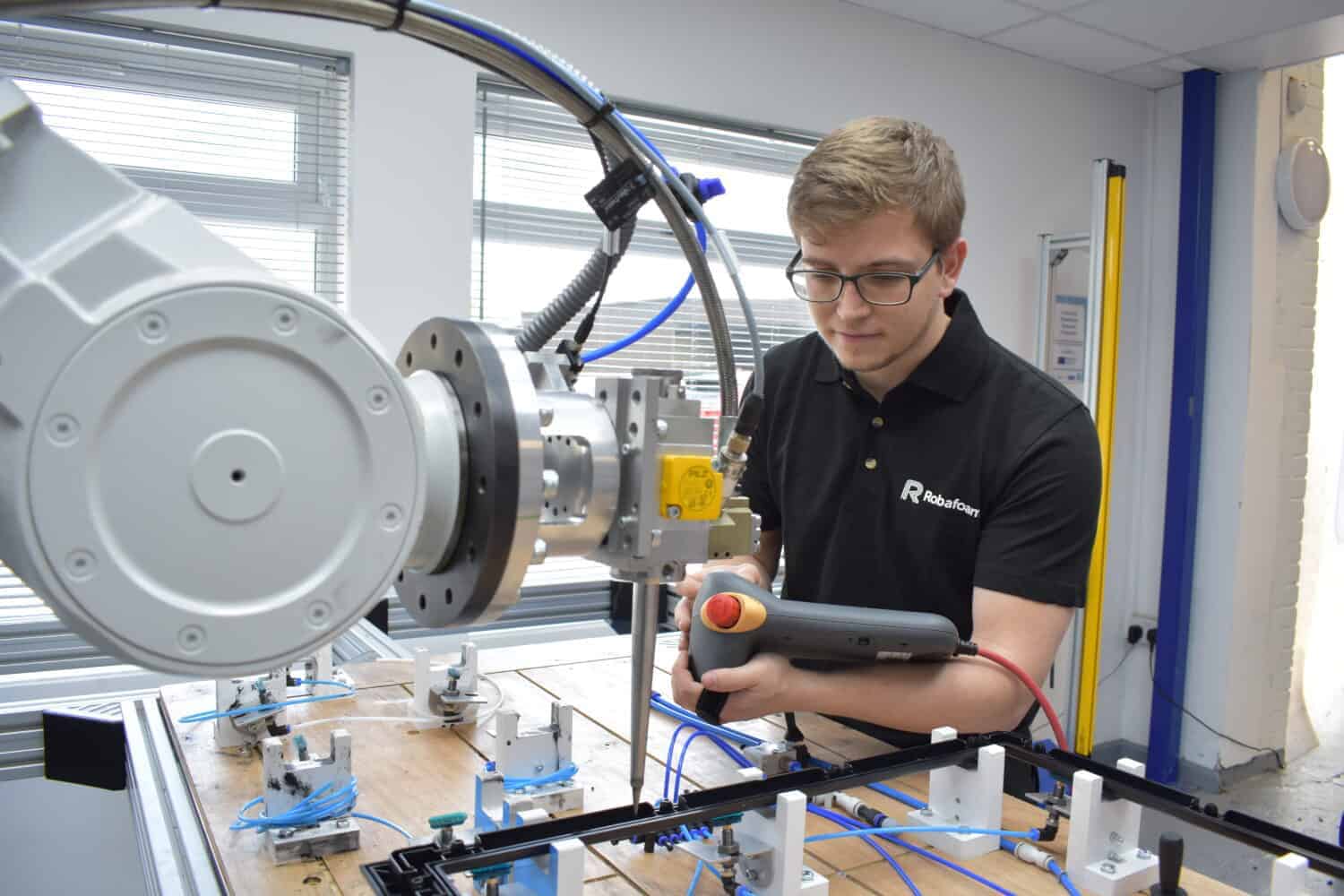

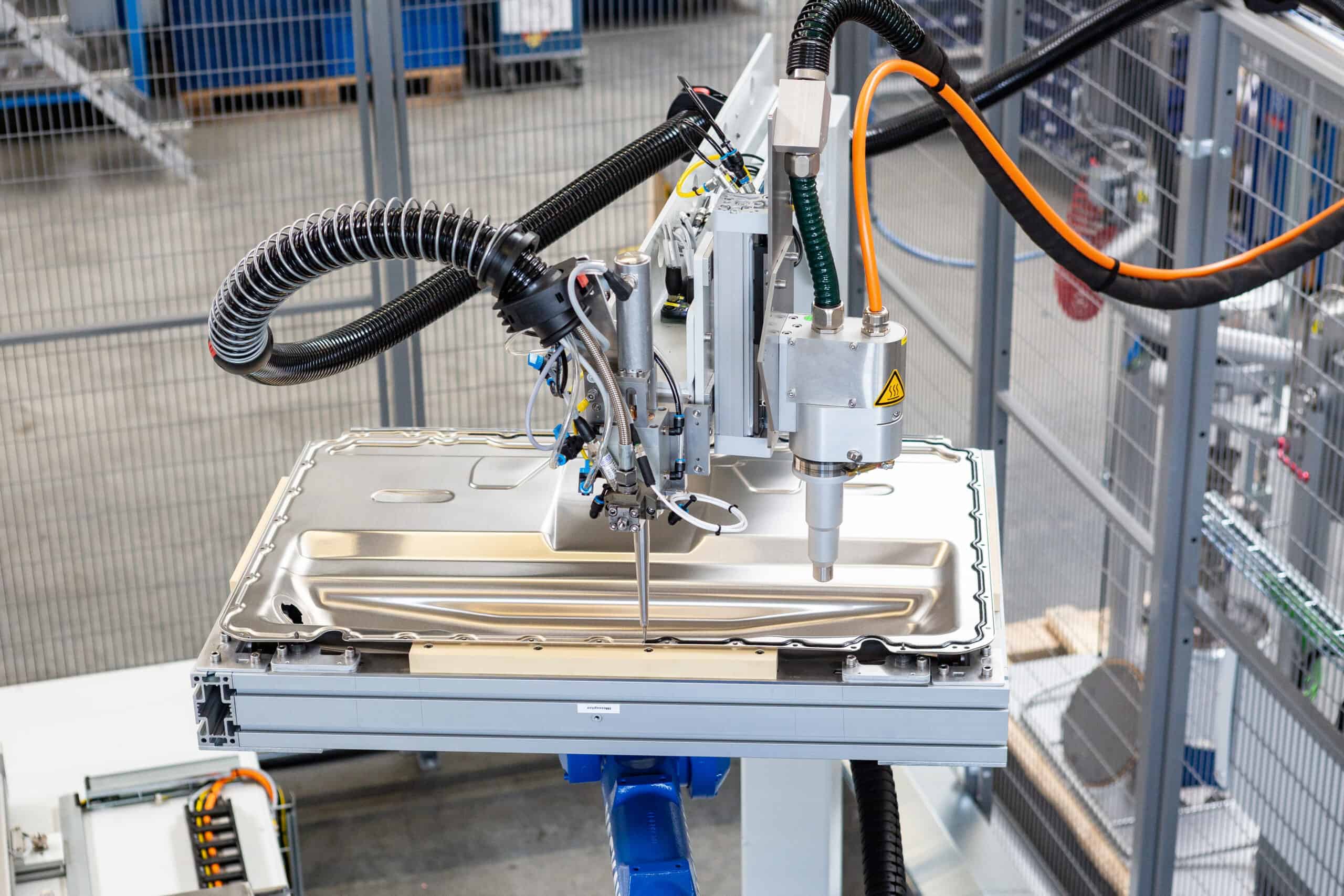

When companies are ready to move on to full production of the part and are through the design and testing process, we can move onto processing the parts in larger volumes at our production facility in Leamington Spa. We refer to this process as Contract Gasketing. This is when the customer sends us the parts, we apply the foam seal using our 6 axis robots, cure it in a thermal oven, repackage the parts and return to the customer. We make it easy for the customer to achieve a high-quality seal without the need to invest in expensive system equipment. We also offer assembly of parts if required and have a dedicated area for them to be processed. Our own vehicle logistics offer a cost effective option for collection and delivery of parts if required.

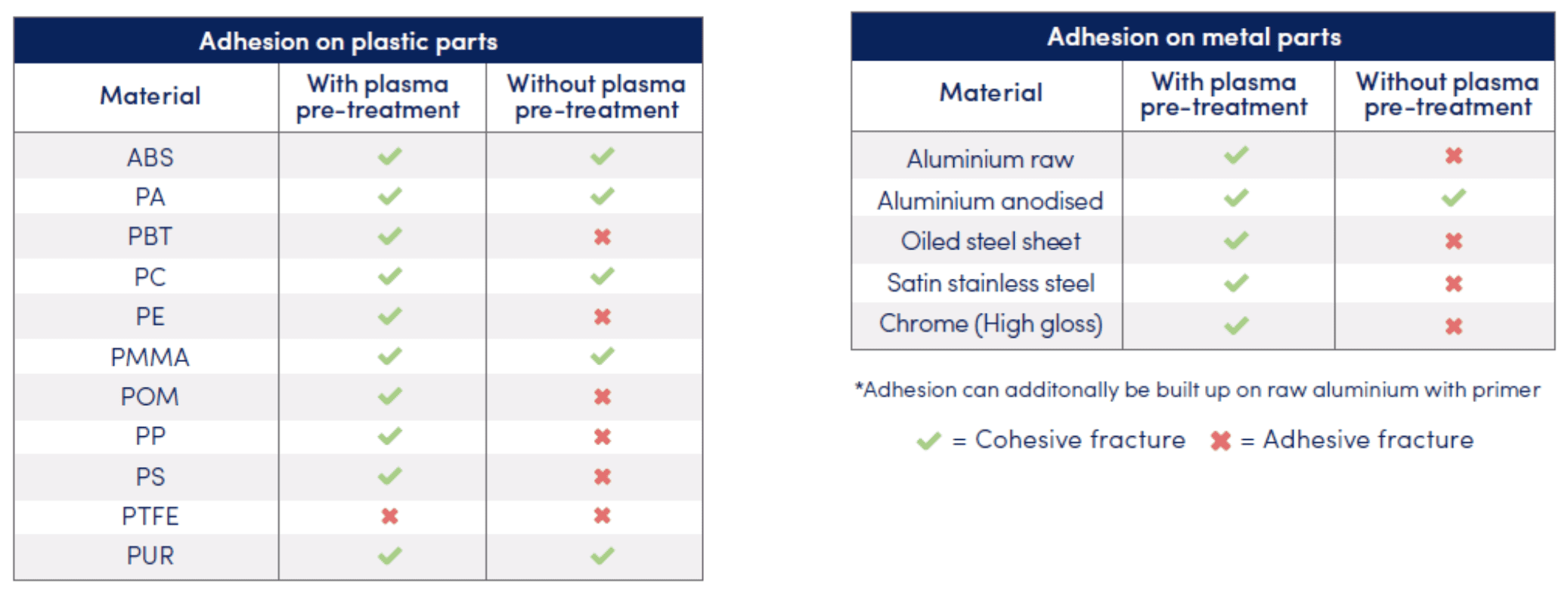

At our site based in Leamington Spa in the Midlands, we run a three shift pattern and have five systems available to process our customer’s parts. Costs are developed based on the processing time of the part, material usage and any additional assembly requirements. If the part requires plasma to ensure adhesion to the substrate (something that may have been investigated in the earlier stages of design/prototype testing), we have plasma systems fitted to all our production cells and offer as part of the incorporated costings of the process time.

We regularly receive requests for support at this stage of the process when a product has begun full production but is failing at testing. Robafoam can offer advice and solutions if companies are having problems with sealing when parts are already in full production. It can limit the options available and can sometimes lead to design adjustments needing to be made but is possible.

System purchasing

For those customers who are producing parts in higher volumes (typically >150,000 parts per year), we are the UK’s supplier for CeraCon foam system equipment for use on the customers’ site. Designed to meet each individuals’ requirements, we can support them in the development of the cell and the type of robot best suited, the size of cell, type of thermal/moisture cure oven and whether plasma is required. As the single point of contact for all the different elements, it makes the ordering of a system as stress free as possible. Once we have supported the equipment’s installation and ensured that everything is up and running smoothly, our assistance doesn’t stop there. We continue to offer servicing support, supply spare parts when necessary and are on hand whenever there is an issue.

For more information on how we can help your sealing requirements, regardless of what stage you’re at in the production of your product, please get in touch with the details on our website.