Since our establishment, our work within the lighting industry has progressively grown and exposed us to some very interesting projects.

Initially, we marketed our sealing technology to complement the UK government’s initiatives to convert to LED systems. The majority of applications were related to either diffuser sealing on glass or plastic substrates, or seals required for the main access cover components; these generally being powdered coated aluminium parts.

In nearly all cases these first applications were introduced to remove manually fitted cord seals. The conversion to FIPFG, improved productivity and reduced the quality issues regularly seen with manually fitted seals. It is increasing IP rating performance and improved service requirements due to the adhesion of our foam to the part surface.

Current Applications

Our foam can be currently found in a range of different lighting applications around the country. Main light seals on street lighting include foam on the diffuser, access covers, body seals and heat sinks. We also do applications for NEMA/Node unit sealing, solar charging units on the streetlights themselves, illuminated street light signage, bollard diffuser sealing and BEV/HEV charging point connections (located within the base of the lamp post).

Testing

Robafoam foam material has been subjected to vigorous testing during its development and continues to be tested to ensure its compliance with a variety of standards, including some of which makes it perfectly suited to the Lighting industry’s requirements. One of these is the ASTM D1003 standard test method for haze and clarity. Our material was initially approved against the ASTM D1003 standard for our automotive lighting applications, however, this is of course a factor for the lighting industry as a whole.

We understand that no two application designs are the same and we can use our expertise to support designers, adapt designs as necessary and seal accordingly, all to achieve the standards required for the specific application.

IP Ratings

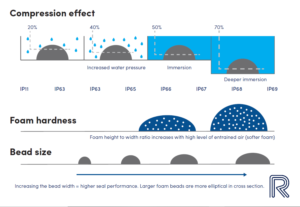

One of the qualities of Robafoam foam material that makes it so suitable for the lighting industry is its ability to provide a high Ingress Protection level (IP rating). By varying the compression, foam hardness and bead size, we can produce a seal that withstands contact with water ranging from water spray to deeper immersion.

Over the past few years, our customer base within the lighting industry has continued to grow which has meant we have taken on a variety of different sealing applications. Our technology is beginning to be known in the industry and our attendance at different exhibitions has helped to increase the awareness of what we do. The flexibility of the foam and its application means that we are able to work with a range of different parts and still produce high quality, high-performance foam bead.

If you work within the Lighting sector and are interested in some more information on foam sealing systems and foam sealing materials, please don’t hesitate to get in touch.