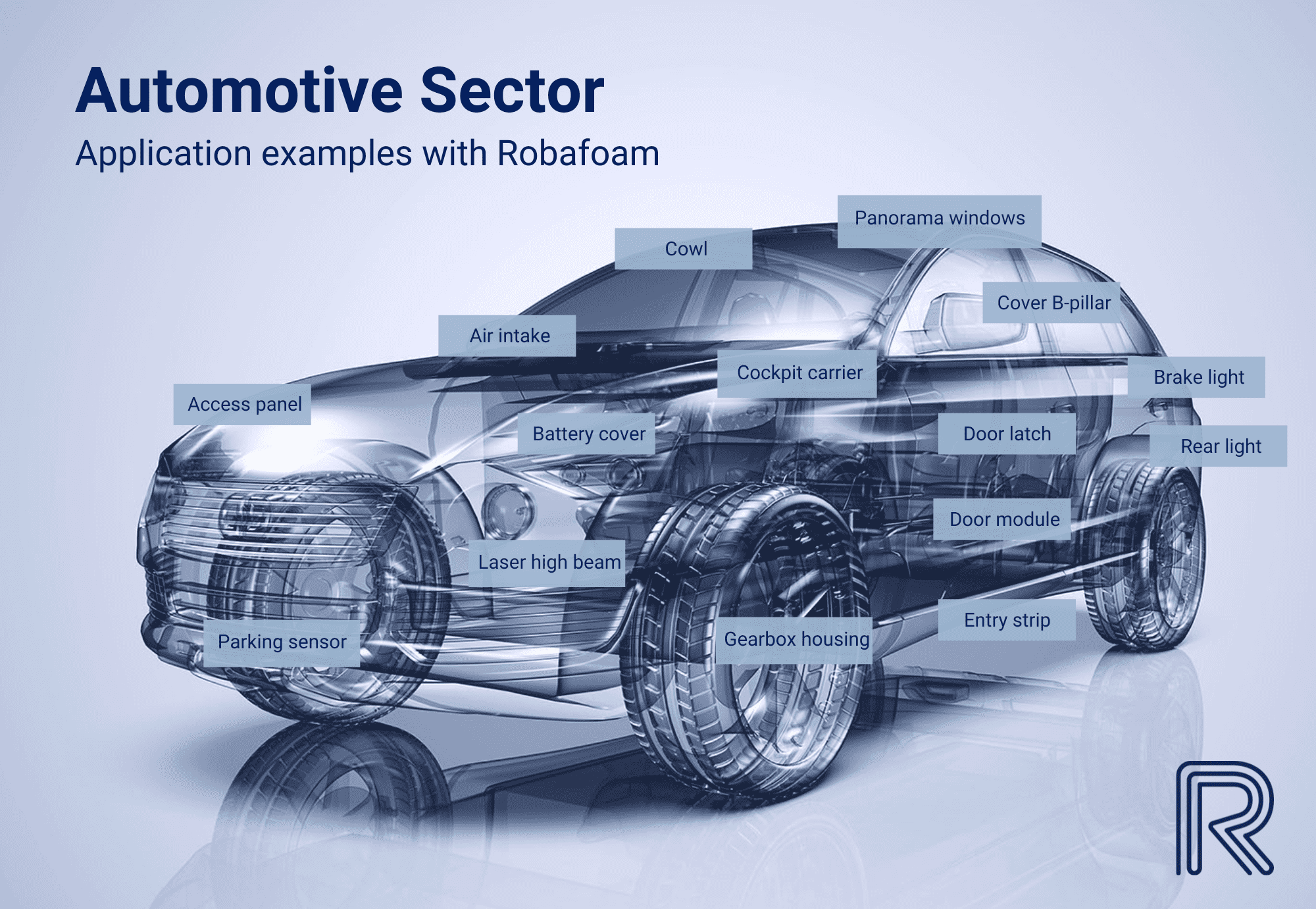

Robafoam has been working with the automotive industry as a foam seal specialist since was established in the UK as CeraCon UK in 2013 and today around a third of our customers are part of the automotive industry. We have a wealth of experience in applying seals to a wide range of parts, for both interior and exterior components. These include door modules, external lighting and roof antennas, to name a few. Our foam is a unique material that performs well on a number of substrates and the application method is so effective that even complex geometries can be sealed quickly and to a high specification.

Robafoam’s foam material uses

Our foam is often used within the industry as a barrier for water ingress and to prevent dirt or other particles from entering the components. However, can also be used to reduce noise and vibration within vehicles. The seals are directly bonded to the parts to make sure that the pad will not move out of place which creates a perfect gasket or cushion application.

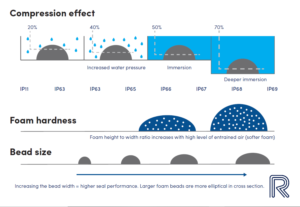

IP rating

One of the qualities that makes our foam material suitable for the automotive industry is its ability to provide a high Ingress Protection level (IP rating). By varying the compression, foam hardness and bead size, Robafoam can offer a seal that withstands contact with water ranging from water spray to deeper immersion.

Testing

Robafoam’s foam has been subjected to vigorous testing during its development and continues to be tested to ensure its compliance with a variety of standards. One of these is the ASTM D1003 standard test method for haze and clarity which means that it can be used effectively within the lighting sector of the automotive industry.

We understand that no two application designs are the same. We can use our expertise in working with the electric vehicle automotive industry to support designers, adapt designs as necessary and seal accordingly, all to achieve the standards required for the specific application. Each part can have the seal customised in size, hardness and design to ensure that specifications from the customer are met.

If you have any further questions or think that Robafoam might be able to assist in a particular application, then please don’t hesitate to get in touch.