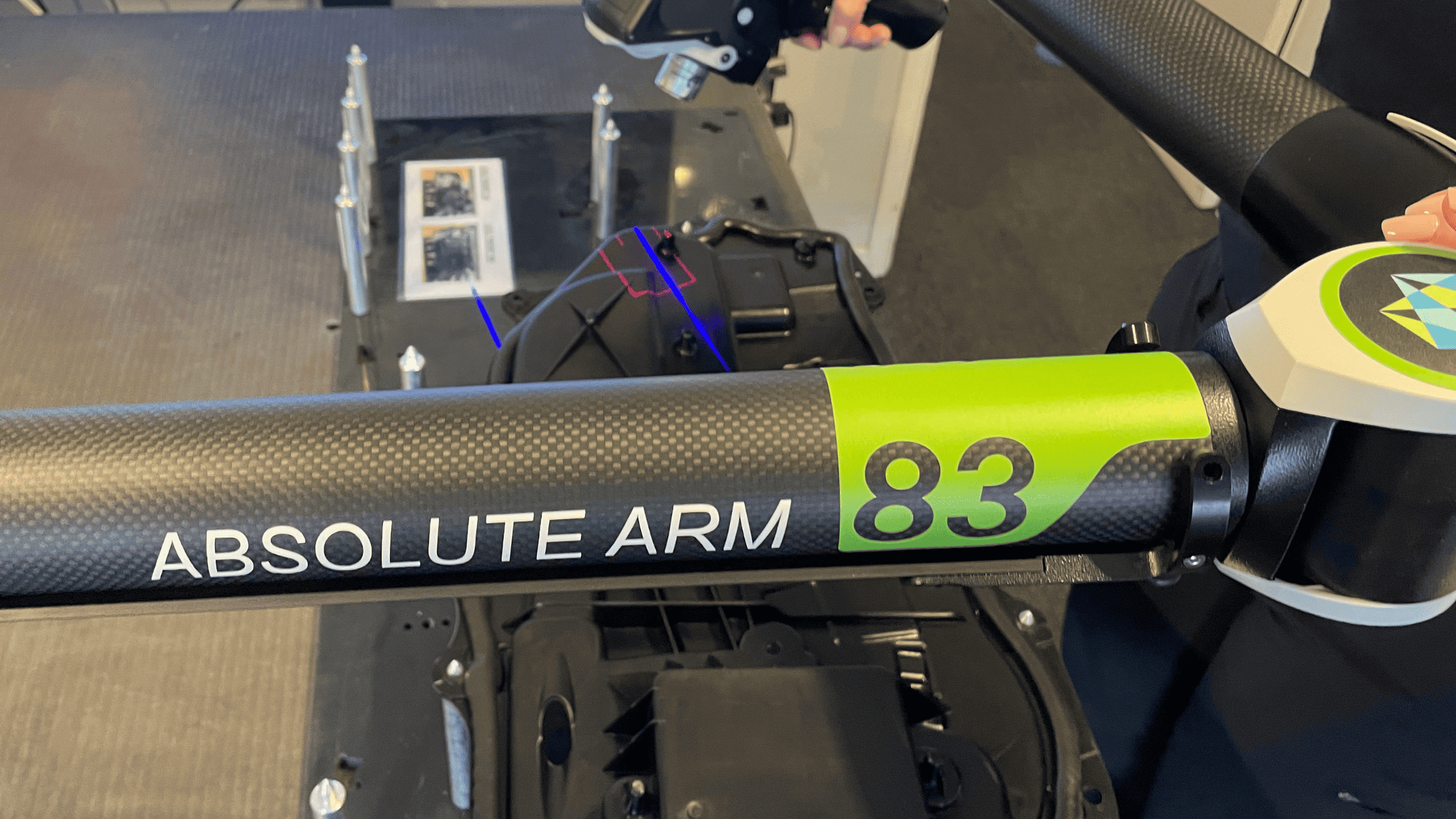

Here at Robafoam, we take great pride in delivering high-quality sealing parts to our customers. We believe that continuous improvement is key to maintaining our reputation as an industry leader. That’s why we are excited to share the news about our latest investment – the Hexagon Absolute Arm 8325. This tool is revolutionising our quality control efforts, enabling us to verify, record and report our production quality and therefore exceed customer expectations. In this blog post, we will take you through how the Hexagon Absolute Arm 8325 is transforming our quality control processes and the significant impact it will have on our operations.

Unveiling the Hexagon Measurement Tool:

At Robafoam, we are always on the lookout for technological solutions to enhance our manufacturing processes. Our recent acquisition of the Hexagon Absolute Arm signifies our commitment to raising the bar in quality control. This new tool combines advance features and capabilities, making it the perfect fit for our quality control needs. With its precise measurements, streamlined inspection, and advance data analysis, we are confident that the Hexagon Absolute Arm will revolutionise our quality control practices and solidify our position as an industry leader.

Enhancing Accuracy and Precision:

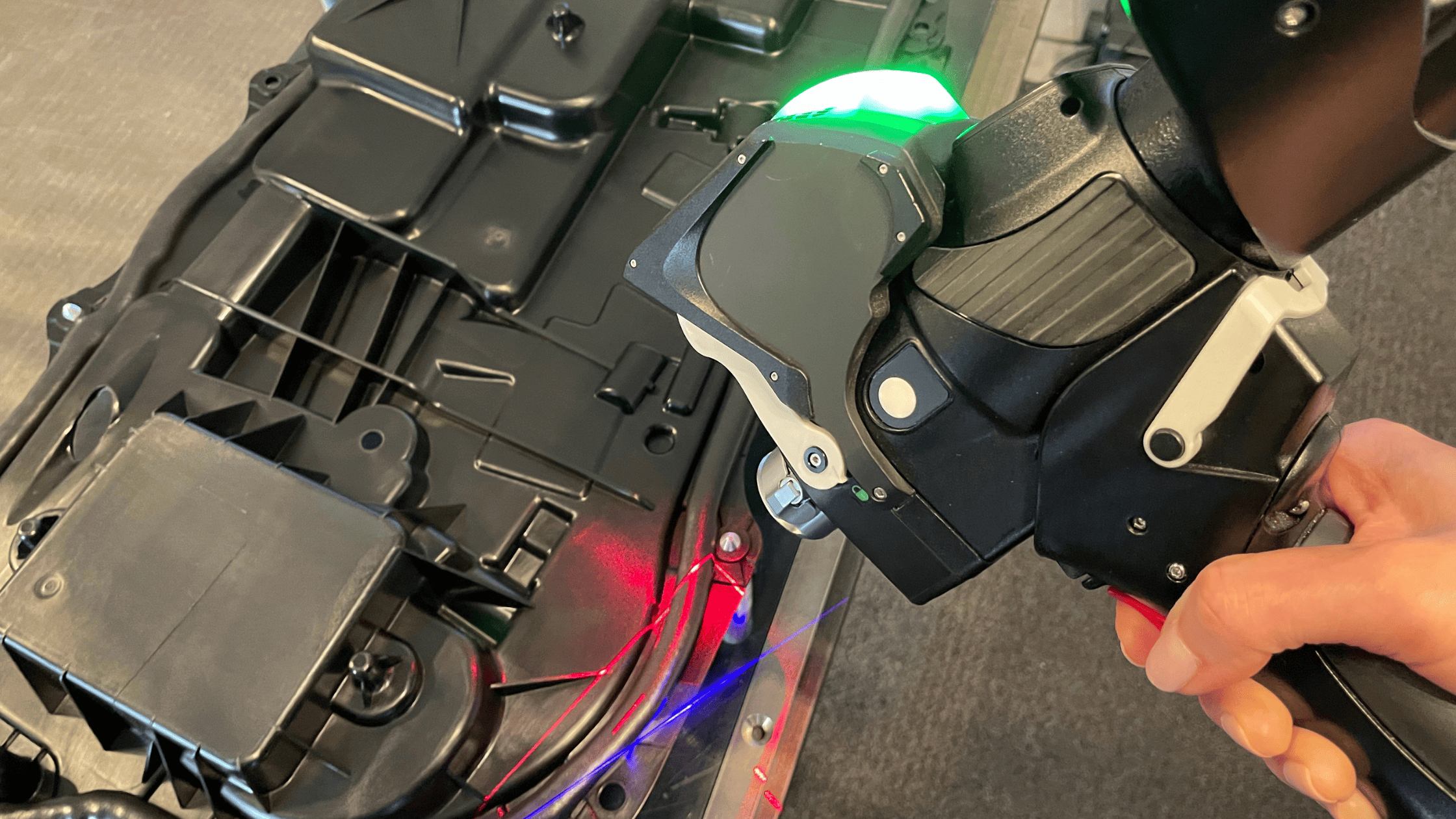

One of the standout advantages of the Hexagon Absolute Arm is its unparalleled accuracy and precision. This advanced tool allows us to capture precise measurements and data, enabling us to identify even the smallest deviations or defects in the sealing of parts. With its 7-axis design, we have the flexibility to conduct thorough inspections at multiples angles, ensuring that every aspect of our parts is meticulously examined.

Streamlining Inspection and Increasing Efficiency:

Efficiency plays a crucial role in our manufacturing processes, and the Hexagon Arm help us streamline our quality control inspection. By automating certain aspects of inspections and integrating advance software, we have significantly reduced inspection times while maintaining a high level of accuracy. The tool’s user-friendly interface and intuitive controls enable our quality control team to work more efficiently, allowing them to focus on analysing the data and making informed decisions. At Robafoam we provide comprehensive training and support to ensure that our team maximises the potential of this new tool. By combining their expertise with the capabilities of this system, we are confident in our team’s ability to deliver exceptional results and elevate our quality control processes.

Driving Customer Satisfaction and Future Growth:

Quality control directly impacts customer satisfaction, and with this system we are dedicated to exceeding our customer’s expectations. By consistently providing high-quality products, we strengthen our relationships with existing customers and attract new clients. This is another step to ensure Robafoam has continued growth and success in this innovative industry. Precise measurement, streamlined inspection, and the advanced data analysis offered by the Hexagon Absolute Arm give us a competitive edge. Enabling us to deliver sealing parts that meet the highest quality standards.