Following on from our recent visit to the Emergency Services Show at the NEC in Birmingham, we thought we would look in more detail at automotive lighting and the sealing requirements they have.

Despite the extensive design process of creating a car, there can still be problems encountered once the car has gone to full production and is being sold on the market. One of these problems is water ingress into the lighting enclosures, resulting in water pooling in the light and eventually a reduction of the effectiveness of the lamp. Sorting this can be costly, which is why effective sealing which is incorporated into the design at an early stage is so important.

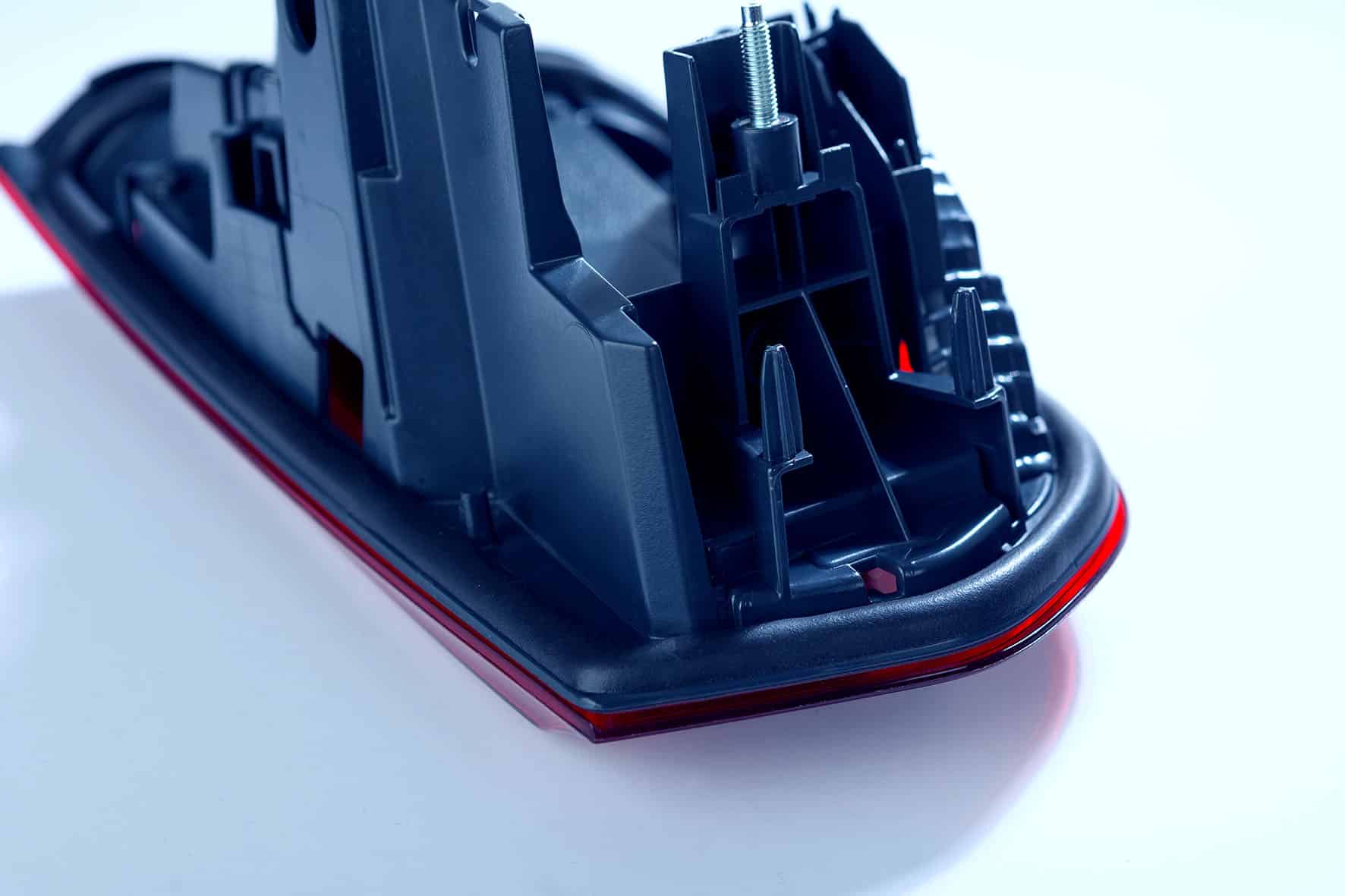

Most commonly, automotive companies were using manually fitted cord seals to prevent water ingress. Although generally effective, these are time consuming to apply and are also subject to human error. Therefore, the conversion to Formed in Place Gaskets, improves productivity and reduced the quality issues regularly seen with manually fitted seals. It also increases IP rating performance, improving service requirements due to the adhesion of foam to the part surface.

Robafoam has been working within the automotive industry since it was established in the UK in 2013 and today around a third of our customers are part of the automotive industry. We have a wealth of experience in applying seals to a wide range of parts, for both interior and exterior components, including lighting.

Robafoam’s foam has been subjected to vigorous testing during its development and continues to be tested to ensure its compliance with a variety of standards. One of these is the ASTM D1003 standard test method for haze and clarity which means that it can be used effectively within the lighting sector of the automotive industry.

We understand that no two application designs are the same. We use our expertise in working with the automotive industry to support designers, adapt designs as necessary and seal accordingly, all to achieve the standards required for the specific application. Each part can have the seal customised in size, hardness and design to ensure that specifications from the customer are met.